10 November 2022 – As pig and poultry producers move towards limiting their use of antimicrobials in production, alternatives to these treatments have become key to addressing pathogen challenges in herds and flocks. But, according to ARM & HAMMER, some are seeing limited success with their use of alternative strategies and it might have the answer as to why.

As the company’s Animal and Food Production Unit’s Technical Services Manager, Dr Sangita Jalukar explained to Feedinfo in a recent chat, some in the industry are still employing alternatives just during a challenge phase, as they would with antimicrobials. The key to success, she believes, is to act preventatively and establish robust health and immunity long before an animal is confronted with these challenges.

And Refined Functional Carbohydrates (RFCs) could be just the tool do so.

In this Industry Perspectives. Dr. Jalukar takes us through why these yeast-derived components, which make up the functional ingredient in ARM & HAMMER’s CELMANAX, are so useful in establishing animal health, reducing pathogen load and supporting immunity. We also dive into the company’s RFC-based, two-step program to tackle pathogen challenges in nursery pigs and how effectively it compares to ZnO. Plus, we dig into CELMANAX’s efficacy in AGP-free broiler production and how it can help support resiliency against common health concerns.

[Feedinfo] Let’s kick off with Refined Functional Carbohydrates. Can you tell us a bit more about what they are and how they differ from other yeasts/yeast-derived products?

|

|

[Sangita Jalukar] Refined Functional Carbohydrates, or RFCs for short, are the active ingredients in CELMANAX. They are derived by a proprietary enzymatic hydrolysis of yeast cells to produce small molecular weight carbohydrates defined as RFCs. Typically, inactive forms of yeast used in animal diets are by-products of alternate yeast processes – such as those employed in ethanol fuel production, and by the beverage and baking industries – and exist in large fragments of the yeast cell wall. These long chain yeast polysaccharides offer limited surface area for interaction with host microbiota and immune cells. Compared to that, RFCs, because of their small size, can easily interact with beneficial and pathogenic bacteria and the host’s immune cells with greater efficiency. |

[Feedinfo] How well do you think the concept of RCFs is understood by the industry, especially in terms of their usefulness in antimicrobial resistance strategies? Are you seeing gaps in the knowledge?

[Sangita Jalukar] The animal production industry is moving rapidly towards reducing the use of antimicrobials and using them judiciously, when needed. But they are looking for alternatives to solve a problem after the fact (after it has occurred). That is not sustainable. They are slow to adopt proactive practices for long term herd and flock health, which will reduce the need of antimicrobials in the first place. The RFCs in CELMANAX are designed to maintain a healthy gut microbiota, reduce pathogen load and enable the host to mount an appropriate immune response quickly when needed, leading to reduced pathogen challenges and need for antimicrobials. And unlike antibiotics, because of the complex nature and mode of action of the RFCs, pathogens are less likely to develop resistance to them

[Feedinfo] So now let’s consider piglets. How has CELMANAX (RCFs) informed your current approach to nursery pigs? What does this entail and how does it differ from what other feed additive makers are promising?

[Sangita Jalukar] Vertical health management plays a big role in livestock and pig production. And this applies to cows and calves, poultry breeders and chicks, and sows and piglets. We believe that healthy nursery pigs come from healthy sows. A young pig’s immune system is still maturing and is susceptible to pathogen challenges. Historically, we have managed that using antimicrobials. Most producers and feed additive makers are now trying to replace those antimicrobials with alternatives in a nursery pig’s diets and are seeing limited success.

What we recommend is a holistic approach, using a two-step strategy to raising pigs without antimicrobials. Step 1 considers farrowing. This involves improving sow health and lactation response to wean healthy and robust piglets which will transition better into the nursery phase. Step 2 is all about nursery management. Good nursery management and farm hygiene are integral to healthy pigs. In addition, the use of one or a combination of research-proven additives can help reduce health challenges, drive feed intake post-weaning and improve average daily gain.

[Feedinfo] What can you share with us on the impact that CELMANAX supplementation can have on sow health and performance, and what evidence do you have that this translates into healthier and more resilient piglets?

[Sangita Jalukar] Our research shows that sows supplemented with CELMANAX had reduced wean-to-estrus (WEI) and an increase in re-breeding. We have also seen fewer CELMANAX-supplemented sows have fever in the first 72 hours postpartum and needing antibiotic treatments. CELMANAX supplementation in sow lactation diets across 10+ trials has consistently shown an increase in piglet weaning weight. And a heavier weaned pig is more resilient and transitions better into nursery.

[Feedinfo] What about supplementation in piglet diets and the impact this can have on key performance factors compared to ZnO?

[Sangita Jalukar] Over the last few years, we have conducted research studies using our two-step strategy with CELMANAX and comparing it with nursery pigs supplemented with and without Zinc Oxide. With CELMANAX supplementation, we could successfully maintain nursery pig performance similar to those fed pharmacological levels of Zinc Oxide. Additionally, CELMANAX improved the performance of nursery pigs compared to those fed diets without any antimicrobials.

[Feedinfo] You’re also putting CELMANAX forward as a solution for AGP-free broiler production. What can you share with us on the product’s efficacy in fostering resiliency against poultry health concerns, like necrotic enteritis, coccidiosis, salmonellosis, etc.?

[Sangita Jalukar] Yes, we have several poultry customers who have made a successful transition from AGP to AGP-free broiler production using CELMANAX. And we have had success because, contrary to antibiotics that may kill good as well as bad bacteria and cause dysbiosis, the prebiotic and postbiotic nature of CELMANAX promotes the growth of beneficial bacteria and improves the immune status of the birds. It has been shown to reduce colonization of certain pathogenic bacteria and food safety pathogens in multiple peer reviewed publications. The combination of a healthy gut microbiota and modulated immune response fosters resiliency and improves growth performance in poultry operations.

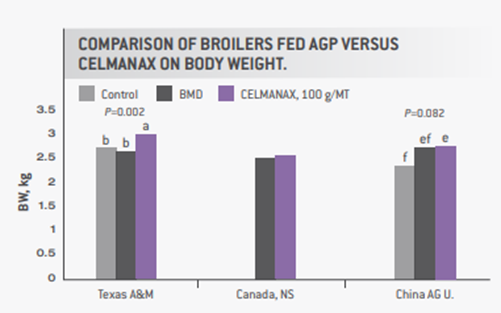

[Feedinfo] And how does it compare as an alternative to AGPs in terms of performance indicators, like body weight and feed conversion? What findings can you share with us?

[Sangita Jalukar] When testing CELMANAX as an alternative to AGPs, the results were clear. Broilers supplemented with CELMANAX had higher body weight compared to broilers fed control diet and similar or higher body weight compared to broilers fed diets with AGP.

|

[Feedinfo] Have you investigated CELEMANAX’s impact on other poultry, like layers and breeders? What findings can you share with us.

[Sangita Jalukar] From a layer and breeder farmer’s perspective, control in vertical transmission of food safety pathogens and productivity and longevity of flock are very important. Our research study in layer pullets challenged with Salmonella showed a 1.2 log reduction in Salmonella colonization when supplemented with CELAMANAX. We have also seen a reduction in environmental Salmonella and in layer mortality, and an increase in egg production.

[Feedinfo] What’s next for RFCs at Arm & Hammer? Is there more to explore here? What new developments are you excited about?

[Sangita Jalukar] We have formulated a mycotoxin mitigation product with RFCs as one of the ingredients and it has been proven to protect against mycotoxin mediated cytotoxicity at the gut level against various mycotoxins. We are also expanding RFC applications beyond pigs, poultry and dairy.

Published in association with ARM & HAMMER Animal and Food Production